All fired up

So, Li took money out of his own pocket and set up a small workshop with several people from the business.

In the beginning, they had to trek tens of thousands of kilometers to find brick kilns to fire up the raw clay models they made.

In 2000, Li brought in electric kilns from Jiangxi and Guangdong provinces, and conducted technical renovations to make them suitable for Nixing pottery production.

Through a process of trial and error, Li managed to raise the yield rate of their high-end products to more than 90 percent.

From that point on, Li never looked back when it came to dreaming of new creations.

He has designed more than 600 Nixing pottery pieces to date, and more than 60 have received awards both at home and abroad. Several pieces have been collected by national museums in more than 20 countries.

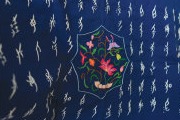

In particular, the piece gaoguhuazun (high drum flower vessel), which artistically integrated ethnic Zhuang and Yao elements with a modern touch, received a UNESCO Seal of Excellence for Handicrafts award in 2006.